Section 2: What else can I spend money on?¶

NOTE THIS IS A ROUGH ROUGH DRAFT

Section 2a: Introduction¶

Upgrades to the Mega V are very common and a frequent generator of questions on the forums is where to source various components for those projects. This page is a fairly extensive list of things I have bought (yes I’m an idiot and no I have not itemized this ever for my spouse :-) ) and tried with my Mega V or used in the past.

Section 2b: Essentials Items¶

| Item | Why |

|---|---|

| Roll in 2020 M5 T-Nuts and Slide in 3030 T-Nuts | Needed to secure items to the T-Tracks after assembly |

| Blue Loctite | To be put on literally every screw to help keep the CNC from shaking itself apart while running. |

| 1-2-3 Machinist Blocks ` | Machinists have used 1 2 3 blocks for years for tramming, making jigs, measuring, and squaring tools keeping it running optimally. |

| 6’ USB Cable with a Ferrite Bead | The Arduino USB ports are highly suseptible to any inteference. A quality USB cable can reall help to reduce problems |

|

The homing switch kit comes with poor quality wire that is too short to be of use. This upgrade replaces the original wire with em shielded heavier gauge |

| Lubricants | If it moves it will need lubricant |

| Brad Ellerbroek’s tramming plate | While this may not be 100% essential it really does simplify the process of tramming the Mega V. |

| Screws | As of mid-August 2020, MillRight seems to now be M4x14mm machine screws for mounting the stepper motors .I still prefer M4x16mm Socket Cap for the added threads securing the motor and the better torque a socket cap can handle. Your call on if you should get these. In any case I do recommend this screw kit or similar just in case you are short something. |

| Feeler Gauges | For measuring gaps |

Section 2c: Spare Parts¶

If you are generating income from your Mega V and this is more than a hobby for you, then downtime is money. A proper set of spare parts is a small investment in insuring your revenue stream doesn’t go away along with your customers satisfaction.

While they don’t advertise it on their site, MillRight will sell you spare parts if you reach out to their sales at support@millrightcnc.com. As noted elsewhere most of the Mega V is commodity hardware which you can source elsewhere some things like the CNC Shield and V-Wheels are custom. I’ve found MillRight to be happy to take my money and ships quickly.

The spare parts that can be purchased from MillRight are:

- 2.5mm Spacers (qty 4) - $2.00

- 6.35mm Spacers (qty 4) - $2.00

- While no sane person would take their Mega V apart as much as the author has, the steppers do need regular checking and those spacers seem to want to escape if given the chance. Spares can be a life saver if you lose one.

- Arduino Uno if 3-Axis (qty 1) - ???

- I don’t have a 3-Axis machine so don’t know what MillRight charges for a spare. If anyone knows please let me know.

- Arduino Mega XL 4th Axis if 4-Axis (qty 1) - $17.00

- You can buy the Arduino’s off the shelf on Amazon but they will need to be flashed with MillRights firmware.

- Mega V Eccentric Spacers (qty 4) - $10.00

- MillRight CNC Shield (qty 1) - $34.00

- MillRight StepperDriver (qty 1) - $36.00

- You may want to consider 2 for this so you can expand the Y to 2 independent drivers

- MillRight KS130 Stepper Motor with longer cable (qty 1) - $35.00

- v-wheels and bearings (qty 8) - $44.00

- I got extra due to some modifications I’m testing out

Other spares that can be bought separately are:

-

Note

A little known fact is that a lot of Ace TrueValue hardware stores carry the replacement brushes for the Dewalt DWP611 router.

Homing Switches

Z Coupler

Section 2c: Computer to Run From¶

CNC’s don’t just run themselves…well not unless you spend a lot more money than you already have but thats a whole different book in need of authoring. While you can run your cuts from the same computer you design from, gcode senders are best run from a dedicated host to minimize interferance if budget allows. The reason for this is that gcode senders must continuously stream g-code to the cnc controller in order to keep the stepper motors smoothly moving and the router cutting. Other tools running in parallel can interfere with this and jeopardize the cuts. If budget doesn’t allow for a dedicated machine, then just be careful that nothing is running on the computer while running a job that could hog the CPU like a Virus Checker.

Choice of computer to use is highly personal and flexble. Windows 10, Mac, or Linux based computers can run all the major gcode senders. Windows 10 is most popular in this space with Linux close behind in popularity. Hardware wise, if being used for just running gcode senders the hardware requirements are minimal. 4GB of ram, and an Intel Atom processor is more than enough to handle the overhead. As a result, shopping Facebook Marketplace, OfferUp, and Craigslist for some ones scrap PC will find you a used computer for as low as $100. Try to find a system with Windows 10 Pro preinstalled if possible to gain the added remote management features.

Warning

Used computers can have all manner of viruses and malware on them. Before doing anything reset windows to factory defaults. Instructions can be found at https://www.laptopmag.com/articles/reset-windows-10-pc

On the forum’s these are examples of a few simple computers that are more than good enough that members have used:

- 10” Windows 10 Fusion5 Ultra Slim Windows Tablet PC- (4GB RAM, 128GB Storage, USB 3.0, Intel, 5MP and 2MP Cameras, Windows 10 S Tablet PC) (128GB)

- These will run from 175-$275 and are a decent small tablet that is windows capable and what the author uses.

- Surface Pro 3 Refurb

- These regularly come up on Woot for around $300 and are a workhorse for a CNC machine.

- LattePanda

- LattePanda - Of the options listed, this is the only one I’ve never seen run (for what little value my opinion asss). This is a tiny windows PC that also comes with an Arduino Leonardo on board (people are using this type of Arduino to make CNC pendants). It will cost $189-$225 depending on windows licenses and will need a case but looks super slick.

- Raspbery Pi 4

- A Linux alternative to a windows computer, that is a fantastic embedded computer that can be run either with or without a monitor which you may see referred to as headless. There is a bit more work involved in setting up a Raspberry Pi but it is more than capable of running machining jobs.

Section 2d: Computer Accessories¶

A wireless keyboard can be a great remote to control the gcode senders. One to consider is:

EASYTONE Backlit Mini Wireless Keyboard With Touchpad Mouse Combo and Multimedia Keys

I use this with a Raspberry Pi 4 and it is a fantastic combo. UGS, CNCJS, and Openbuilds Control all support keyboard based jogging. Beaver CNC has a good video tutorial on using this keyboard with CNCJS.

Artik Raspberry Pi 4 Case with GPIO Extension Header

The Raspberry Pi 4 runs hotter than the prior generations and a heatsink case is a good idea for managing that heat.

USB Hubs with power switches on the ports come in super handy. The controller seems to need the USB cable unplugged often and the power switches make this really easy to do.

Section 2e: Endmills¶

Warning

Amazon is full of Whiteside counterfeits. Check the comments and reviews of any endmill you order from them. People tend to call out fakes. I won’t buy Whiteside from Amazon after receiving a counterfeit surfacing endmill.

Warning

Measure the shank of all endmills you receive especially from chinese imports. Sometimes a metric endmill won’t have a true 1/4” shank and the collet can’t hold it firmly and you’ll see runout and uneven depth of cuts from the slippage.

Endmills are complex enough that they deserve their own book. It is my belief that a good starter set of endmills consists of:

- 1/4” shank 1/4” diameter 2 flute upcut

- 1/4” shank 1/4” diameter 2 flute downcut

- 1/4” shank 1/8” diameter 2 flute compression

- 1/4” shank 1.0mm tip ball nose (if 3d carving)

- 1/4” shank 1” or 1.5” spoil board surfacing endmill

- 1/4” shank 60 degree v-bit

- 1/4” shank 90 degree v-bit

If carving aluminium you may want to buy special coated upcut endmills that will resist aluminum sticking and generally last longer. Common coatings are Titanium Nitride (TiN) and the even harder Titanium Carbon Nitride (TiCN). There is a lot of debate on number of flute’s for aluminium. The accepted wisdom is 1 flute so that it makes larger chips which pulls heat aware from the cutting surface. Many Mega V users report chatter with 1 flute and suggest 2 or even 3 flute cutters as they make more and smaller chips resulting in a higher quality finish. Over 3 flutes seems to hurt rather than help as the chips are too small to eliminate heat. Given all this, my suggestion is buy some cheap endmills to experiment with and then decide on if its worth the fancy coatings. I’ve been shocked at how well a $2 cutter can perform.

Etching Acrylic and Tile comes up a lot as something people want to do. While it can be done with a v-bit, there are special drag bits that can give a more detailed finish in acrylic and granite.

Drag Endmills

Section 2f: Trustworthy EndMill Vendors¶

Amazon¶

Beware the counterfeits, but informed is protected. Amazon is great for finding both quality and cheap endmills to try out. Some noteworthy options are:

Hobren¶

While Amazon can be challenging for sourcing Whiteside bits I’ve had excellent service from Holbren and they have decent pricing.

Tools Today¶

They may not be the cheapest but they stand behind their products with an amazing 6 Month Warranty where you can return anything for 6 months for any reason. They have replaced endmills I’ve dropped on the floor for perspective. Don’t abuse the generosity but if you are buying higher end endmills consider giving them your business. Also, follow their Instagram where they post tons of CNC content https://www.instagram.com/toolstoday/

Carbide Plus (aka drillman1)¶

drillman1 has been a vendor on ebay selling very reasonably priced endmills with super quick shipping basically forever. I’ve bought many times from this store with zero issue and they are a very reputable vendor.

Carbide Tool Source (aka roguesystemsinc)¶

This is an American company run by 2 guys based in Oregon that manufacture all their products in-house and sells on ebay with no middle men. They carry a huge line of products with some very specialized endmills you don’t see at many other stores. If you’ve ever wondered where to get an endmill for an 80% lower look no more. I found their products to be high quality and I’m always one to support a small business where I can.

Local Big Box¶

Desperate times call for desperate measures, and most people don’t realize that Lowes and True Value stores carry a small selection of CNC endmills. If you have a project due and you just broke your last endmill this can be a life saver.

Section 2g: Useful Tools¶

I very much follow the Adam Savage rule of “Buy it from Harbor Freight then buy it for life when that breaks”. This list of tools are suggestions and no one should run out and buy all of these unless you have a burning desire to spend an awful lot of money. When deciding if your Big Box Square is good enough vs something like a Woodpecker square I found the video https://www.youtube.com/watch?v=vVeqY0LI5Dc to be a good comparison of low versus high end. Disclaimer I don’t work for WoodPecker they just seem to find an awful lot of my paycheck deposited in their bank account.

Calipers¶

Drill bits¶

- Metric M42 8% Cobalt Twist Drill Bits Set for Stainless Steel and Hard Metal (1mm-10mm/19pcs)

- Metric drill bits are hard to find at big box stores (I once spent hours on a futile quest for an M4 drillbit) but come in handy when taping holes for the CNC and since so many CNC accessories use metric.

Screw Drivers and wrenches¶

- Wera Kraftform 7440/41/42 Torque Screwdriver 0.3-6.0 Nm and Bit Set, 27-Piece

- I’m an engineer and like precision, with this screwdriver you can control the torque as you tighten each screw perfectly. While purely subjective they also feel awesome when using them.

Squares¶

Tape measures¶

Tap and Die Sets¶

Measuring and Marking Tools¶

Woodgraphic Professional Dual Function Vernier Calipers for Measuring and Marking

The Woodraphic tool is one of those tools that surprised me in just how often I use it. This tool is great for helping ensure your racks are all evening spaced and for testing positioning of things.

Woodpecker PAOLINI POCKET RULES

This is is a fantastic layout tool for Woodworking and not the typically insane pricing from Woodpecker. It’s a gateway drug though so wallets beware.

1-2-3 blocks¶

- BL-123 Pair of 1” x 2” x 3” Precision Steel 1-2-3 Blocks

- Used for jig making, testing square, CNC calibration, and a million other things depending on your creativity.

Feeler Gauges¶

- Hotop 32 Blades Steel Feeler Gauge Dual Marked Metric and Imperial Gap Measuring Tool

- Harbor Freight PITTSBURGH AUTOMOTIVE Feeler Gauge, 32 Pc

- Used for testing the thickness of a gap. Very useful for getting consistent pinon spacing on the stepper motors, tramming the router, and identifying how much shimming is needed to square a portion of the Mega V.

Cutting Fluid¶

- Tap Magic 20004A Aluminum, 4 oz.

- If you are cutting aluminium extrusions on a miter saw or milling blocks of 6061 this is a great cutting fluid to use.

- Oatey 16 oz. Dark Thread Cutting Oil

Section 2h: Grounding Aids¶

Ground loops as well as missing grounds while not a problem on every setup can cause drop out’s mid-cut, as well as an inability to connect over USB to the CNC Controller. Cutting certain materials like Acrylic and MDF will generate significant amounts of static electricity. If you find you are failing cuts when working with these materials then you likely have a grounding issue. If this starts happening there are a several potential solutions:

- Split the load between 2 or more electrical circuits ShopVacs tend to not play well with others when sharing a circuit.

- Shield all wires and earth ground at least 1 end of each.

- Put a hub between the computer and CNC Controller. Not all USB ports were created equally and a decent USB hub can smooth out a surprising number of issues.

- Use a USB cable with a ferrite bead

- Use a USB Ground Isolator.

All of the following can help with these issues:

- USB Cable with a Ferrite Bead

- iFi iDefender+ External USB Audio Ground Loop Eliminator (A to A)

- USB Ground Loop Protection

OR

- HiLetgo ADUM3160 B0505S 1500V USB to USB Voltage Isolator Module Support 12Mbps 1.5Mbps

- ESD Grounding Cable with Alligator Clip 16.5 Feet - FEITA Ground Cable Cord Clip EMF Radiation Fabrics, Plug into Your Outlet Ground

- Superior Electric EC183 9 Feet 18 AWG SJO 3 Wire 125 Volt Electrical Cord

- Grounded Power Cord for Dewalt Router

Section 2i: Wasteboard Accessories¶

T-Nuts¶

- For mounting to the rails under the gantry

Threaded Inserts¶

- E-Z LOK 400-4 Threaded Inserts for Wood, Installation Kit, Brass, Includes 1/4-20 Knife Thread Inserts (5), Drill, Installation Tool

- E-Z Lok Threaded Insert, Zinc, Hex-Flanged, 1/4”-20 Internal Threads, 25mm Length (Pack of 50)

- E-Z Lok Threaded Insert, Zinc, Hex-Flanged, 1/4”-20 Internal Threads, 13mm Length (Pack of 100)

Fences¶

- PwnCNC Wasteboard Fence Guide

- Wasteboard fences can certainly be made (you own a CNC after all), but these are great for having a squared start position for your cuts.

Section 2i: Dust Control¶

Proper dust collection is important when milling. Products like MDF produce a tremendous amount of dust when being milled. That combination can cause fires, and generates a lot of static when collected. CNC Controllers can be very suseptible to static build up and a grounded dust hose like this is a good part of a holistic approach to static management.

Warning

Dust from MDF, FR1 (PCB), Phenolic and a slew of other things consists of very fine particles that can cause long term lung damage. Whichever dust management system you use it is strongly advised that it be HEPA rated so the fine particles don’t just blast out the dust port. Dust control should always be paired with a proper respirator. Lungs are a terrible thing to waste.

Cyclone Separator¶

Cyclone Extrators pull the heavier chips out of the vacuum stream before it reaches the bag and HEPA filter. This saves a lot of cost on expendables.

Dust Boots¶

Dust Collectors¶

Grounded Dust Hoses¶

Section 2j: CNC Add-ons and Add-on Shops¶

Collets¶

Precision Collets reduce runout in a CNC which can cause inaccurate cuts as well as possible endmill breakage. Collets come in various sizes and stocking specific ones for 1/8” or even 1/16” endmills is preferable to a reduction collet insert.

Coolant Systems¶

Drag Chains¶

- URBEST 15mm x 40mm Black Plastic Flexible Nested Semi Closed Drag Chain Cable Wire Carrier 1M for Electrical Machines 15mmx40mm

- This model is a little larger the the MillRight Drag Chain and gives a bit more room for the added size of shielded wires.

Lasers¶

- Wixey Model WL133 Drill Press Laser See this post documenting how the laser was used for consistent starting point location https://www.facebook.com/groups/243620779833403/permalink/698593764336100/

Power Control¶

Wasteboard Reinforcement¶

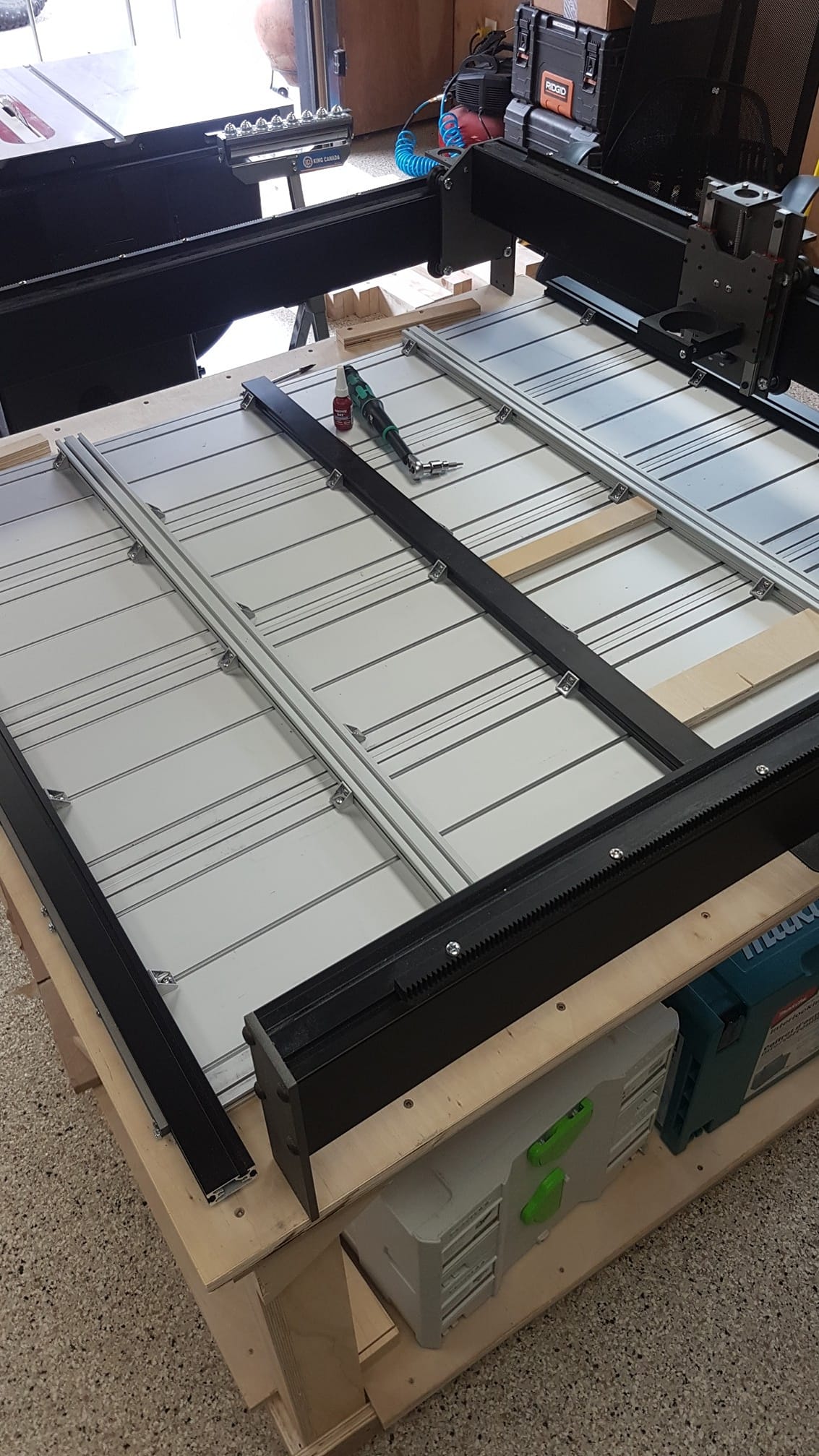

- Aluminum Extrusion 48” (1220 mm) Clear Anodize Misumi Series 5 (20mm x 40mm) - 4 pack

- Millright ships a single central cross brace for the T-Track Bed as part of the assembly kit. Several forum members and I have added 2 extra 1000mm long 2040 extrusions on either side of the included one to further support the bed. This link is to a 4 pack of longer extrusion that I have bought and then cut down on a miter saw. Extrusion has a million uses so extra never hurts. Nothing says you can’t just source 2 1000mm pieces though from Misumi, 80/20, or Faztech.

Section 2k: CNC Repair and Replacement Parts¶

Lubricants¶

Coupler Alternatives - Z-Axis¶

Loctite¶

Do not use red loctite or you will never be able to remove the screwa. Blue is what should be used with the CNC.

If the pinons are slipping down the shaft of the stepper and blue loctite isn’t enough then marine epoxy is a more permanent fix

Screws¶

The following are used with the replacement stepper motor caps in 3d prints

- uxcell M3x35mm Thread Button Head Hex Socket Cap Screw Bolt 50pcs

- uxcell M3x70mm Fully Thread Hex Socket Head Knurled Cap Screw Bolt Black 10pcs

The following are used for mounting the stepper motors

These kits come in handy for those “oh crap I’m short a screw” moments

Stepper drivers alternatives¶

MillRight uses analog drivers for the 4 steppers in the Mega V. If replacements are needed they can be ordered from Millright or you can switch them for quality digital drivers. The following are drop-in replacements:

- STEPPERONLINE Digital Stepper Driver 1.8~5.6A 20-50VDC for Nema 23, 24 Stepper Motor

- https://www.automationtechnologiesinc.com/products-page/kl-stepper-drivers/kl5056/?fbclid=IwAR1WmpWmxFA0UqM2xDiblJYAH9gS5jLUW2gCbR_czpnPi14KRwdbEdqnjeY

- https://www.stepper-store.com/product/digital-stepper-driver-1-85-6a-20-50vdc-for-nema-23-24-34-stepper-motor/?fbclid=IwAR3Or490m7iClHHKZOjOOC-mNEuxbtq89aimxLk26H1PWbssoOF7wm1zjvk

- https://www.omc-stepperonline.com/digital-stepper-driver-18~56a-20-50vdc-for-nema-23-24-34-stepper-motor-dm556t.html?fbclid=IwAR0Mifi4nC-F2McjOtrKxgyZm75PqIsOzE0q8na-JY6ef5ozj4BSLVXtHPM

Vendors with a wide range of parts that you may need¶

Section 2x: Work Holding¶

- Low Profile CNC T-Track Clamps - Set Includes 4 Clamps

- Carbide3D Gator Tooth Clamps

- Carbide3D Corner Square

- Carbide3D Tiger Claw Clamp

- Kraken3d Low Profile CNC T-Track Clamps

- The Blue tape method was created by NYCCNC and consists of painters tape and CA glue. See <> for video of the process

- Starbond EM-150 Medium, Premium CA - Cyanoacrylate Adhesive Super Glue

- Starbond Instant Set ACCELERATOR (Activator) for CA Super Glue

- APT, (Multi-Sizes)2 Mil Polyester Tape with Silicone Adhesive, PET Tape

- Blue Painters Tape

- An alternative to CA Glue and Tape is XFasten Double Sided Woodworking Tape

Section 2k: 3D Printing Accessories¶

Brass Heat set Inserts

- [ J&J Products ] M3 Brass Insert, 5 mm (Length), Female Thread, Heat Sink/Injection Mold Type, 100 pcs

- McMaster Carr M5 Brass Inserts pack of 50

Epoxy

Section 2l: Cabling Making Parts¶

Connectors¶

Aviation connectors are what MillRight uses on all their cables and the control box

If replacing the cables with shielded wiring AND building a new control box the Molex mini-fit line of connectors are a clean way of mounting cables. These are the parts I used

- 39-00-0040 (MALE) MN-FT TERM 18-24G F Reel of 1000

- 39-00-0038 (FEMALE) MN-FT TERM 18-24G F Reel of 1000

- 39-30-1060 6CKT RECPT HSG <https://www.mouser.com/ProductDetail/538-39-30-1060>_

- 39-30-1040 4CKT R/A HEADER

- 45559-0002 6CKT RECPT HSG

- 39-01-3045 MINI FIT REC 4CKT 55 EC 4CKT 555704R BLACK

- ` 204723-0006=4 BackShell 4ckt LH Blk <https://www.mouser.com/ProductDetail/538-204723-0004>`_

- ` 204723-0006 BackShell 6ckt LH Blk <https://www.mouser.com/ProductDetail/538-204723-0006>`_

If adding shielded wiring Neutrik connectors are nicer (and more expensive thank aviation plugs but are worth looking at

Tools¶

- Ferrule Crimping Tool Kit - Sopoby Ferrule Crimper Plier (AWG 28-7) w/ 1800pcs Wire Ferrules Kit Wire Ends Terminals Ferrules are metal tips that can crimp onto wire ends rather than putting bare wires into screw terminals. While not needed, if you find yourself rewiring your control box then putting htese on everything is a nice to have.

Cables¶

18/2 Shielded Wire for Homing Switches

- Belden 5300FE 18/2 Shielded Control Cable 100 Ft

- PLTC3-18-1S-1

- C2G 29204 18 AWG Bulk Speaker Wire - Shielded, Plenum CMP-Rated, White Jacket (50 Feet, 15.24 Meters)

22/2 Shielded Wire for Homing Switches

18/3 Shielded wire for Proximity Switches

18/4 Shielded Wire for Stepper Motor Replacement Cables

- Canare L-4E6S Star-Quad Microphone Cable by the Foot

- Belden Wire 6302FE 18/4C Shielded Control/Speaker/Audio Cable Plenum White/100ft

16/4 VFD Cable

- VFD Cable: 16 AWG, cut to length (PN# VFDC-16-4B-1)

- When you buy a spindle they generally don’t come with the power cord which you need to solder onto airplane connectors.